History of the Hard Hat

From the Hard Boiled® Hat to Today's Skull Bucket: A History of Hard Hats

When were the first hard hats manufactured? How has the design changed through the years? Who manufactures the six million “skull buckets” sold each year to protect workers’ heads?

The hard hat concept comes from Bullard, a hundred-year-old, family-owned manufacturer of personal protective equipment, specializing in industrial head protection, including hard hats, firefighter head protection and supplied-air respiratory protection.

History of the Hard HAT

A hundred years ago, the hard hat didn’t exist. And fifty years ago, head protection wasn’t widely required for workers. But, thanks to advances in safety, the hard hat has evolved over the decades.

Established in San Francisco in 1898, Bullard sold carbide lamps and mining equipment to gold and copper miners. “The miners used to wear a soft derby, similar to a baseball cap. It had a small, hard-leather and shellac brim,” said Edward D. “Jed” Bullard, Chairman of the Board and former President and CEO.

In 1915, my grandfather began work on a helmet that could protect miners from falling objects. He based it on the doughboy, a helmet he’d worn as a soldier in World War I. The ‘Hard Boiled® Hat’, patented in 1919, was so called because of the steam used in the manufacturing process,” said Bullard.

“The original ‘Hard Boiled® hat’ was manufactured out of steamed canvas, glue, a leather brim, and black paint. My grandfather built a suspension device into what became the worlds’ first, commercially available, industrial head-protection device.”

First Designated ‘Hard Hat Area'

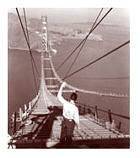

America’s first designated “Hard Hat Area” was set up at the San Francisco Golden Gate Bridge construction site. “The project’s chief engineer, Joseph B. Strauss, shared a vision with my grandfather that the workplace could be a safer environment for the worker. One problem the bridge project faced was falling rivets, which could cause serious injury,” said Bullard. “My grandfather transformed the mining helmet into a durable industrial hard hat.”

The project faced a second problem with the steel coming by train from Bethlehem, Pennsylvania-it oxidized, and needed to be sand blasted before being painted. My grandfather designed a simple sand-blast respirator helmet-basically a hard hat with a bag over it. There was a window to see through, and fresh air pumped into it. That was the beginning of our respiratory-protection business.”

In 1938, Bullard designed and manufactured the first aluminum hard hat, which was considered very durable and reasonably lightweight for the time. “Even today, a few clients still have their 25-year-old aluminum hard hat,” said Bullard. “These hats have one serious drawback, aluminum is a great conductor of electricity.”

Bullard’s distinctive three-rib, heat resistant fiberglass hard hat was developed in the 1940’s. In the 1950’s and 1960’s, thermoplastics replaced fiberglass because the newer material was less costly and better suited for the applications. Bullard was one of the first manufacturers to inject thermoplastic into a mold to produce a hard hat.

In 1982, the standard hard hat changed again. The director of safety at Bechtel Corporation, one of Bullard’s major clients, felt that hard hats didn’t have the proper suspension for field work. In response, Bullard introduced a new helmet that incorporated a non-slip ratchet suspension with a knob in the back for simple sizing.

Today's Yellow Hard Hat

Within the industry, the hat became known as the “3000 R”. The 3000 R was produced from polyethylene plastic-making it lightweight, durable, easy to mold and non-conductive to electricity. The plastic was treated with an ultra-violet inhibitor which helped the hats weather the outdoor environment.

Bullard redesigned the 3000R and introduced the C30, presenting a significant advancement in worker comfort. Enhanced with an upgraded suspension system, the C30 incorporates easy-lock snaps for simple installation, an improved FlexGear® for easy height adjustment, and an enhanced brow pad. Offer the most advanced comfort in the market, the C30 has become known as today’s standard yellow hard hat.

Unprecedented changes have occurred in the last ten years. “A great deal of our knowledge comes from designing firefighter helmets,” said Bullard. “We’ve been able to apply research on applied energy absorption to the industrial setting.”

From that knowledge, the Advent® and Vector evolved. At 25 ounces (709g) the Advent is half the weight of conventional firefighter helmets and is, in fact, the same weight as many climbing helmets. The Advent is the only protective helmet designed specifically for emergency response services.

The compact design is unique. “Not having a rear brim improves freedom of movement both in and out of emergency vehicles and confined spaces,” said Bullard. “A crown pad, and a soft, replaceable, foam-backed vinyl brow pad provide extra comfort. It costs less than half the price of conventional fire helmets, and can be equipped with a variety of accessories, including face shields, ear/neck protectors, hearing protectors and attachments for lamps.”

The Vector is the off-shoot of the Advent. “The Vector provides impact protection for the top, front, back and side of the head,” said Bullard. “It uses a full inner shock liner to absorb impacts.” The Advent can come with a brow pad, comfortable suspension, built-in goggle strap and retaining slots. The Vector, along with the Advent, are the first caps to meet the newest ANSI standard for industrial head protection.

After gathering input from end-users in the field, Bullard designed the vented hard hat, known as the S62. “The standard complaint we heard about hard hats was that they’re too hot,” says Bullard. “With this in mind, we went to work and came up with a hat that will help keep workers cool.” Featuring a vented shell, the S62 allows air to flow inside the hard hat, keeping the user cool and comfortable while providing quality protection.